Inside the Edge: A Professional Look at the Hair Shear Sharpening Process

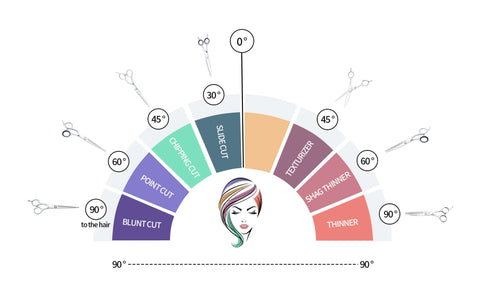

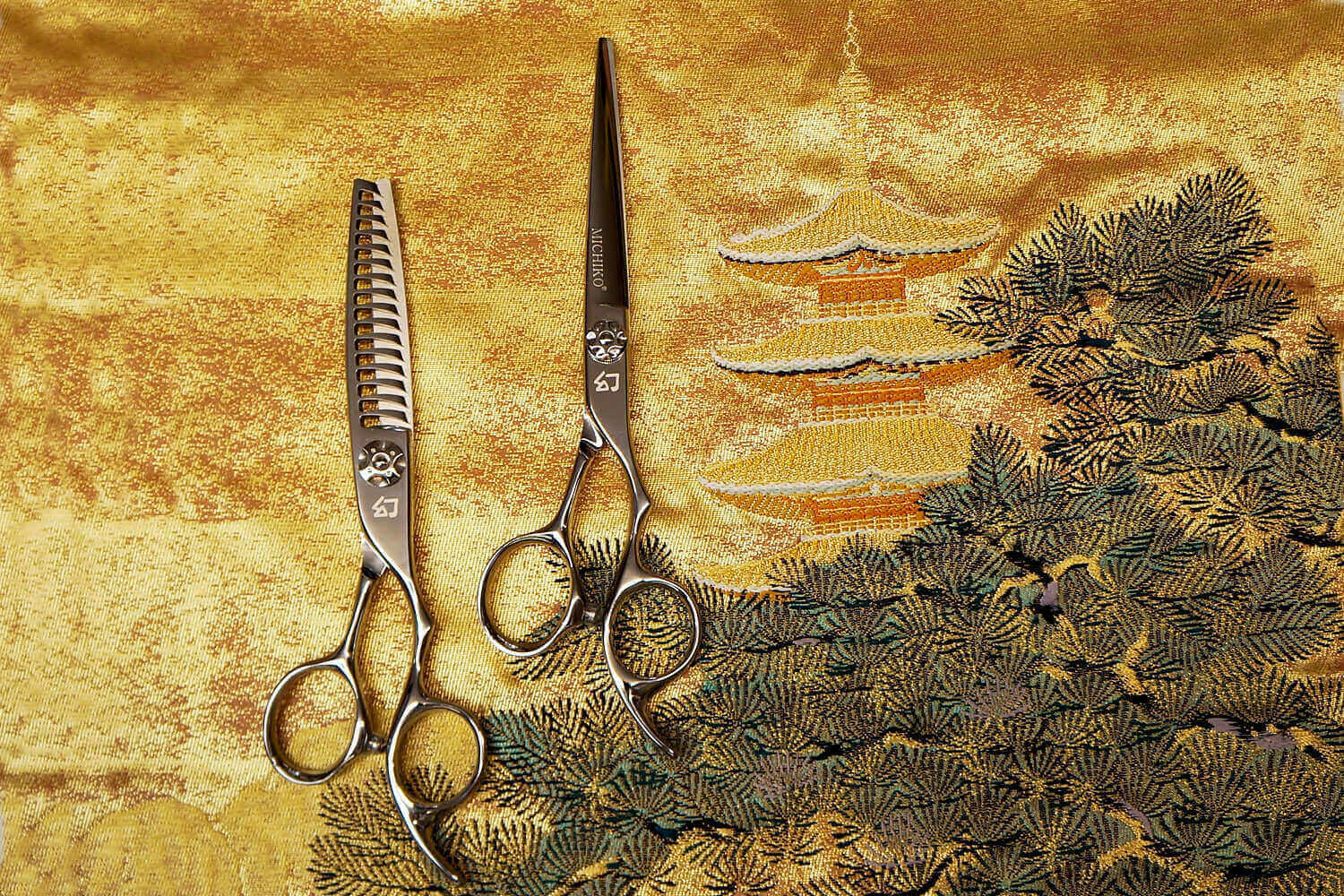

Hairdressing scissors are precision instruments—refined tools that demand expert care to perform at their best. Whether you’re a seasoned stylist or an aspiring barber, keeping your shears in peak condition is essential to protect your investment and deliver clean, smooth cuts every time.

In this post, we’ll take you behind the scenes of a professional sharpening process, breaking down each step from inspection to finish. Our method combines traditional Japanese techniques with modern precision to restore your shears to their optimal performance.

1. Inspection: Every Edge Tells a Story

Before we sharpen anything, we inspect every shear carefully. This step is essential to identify signs of wear, micro-chips, blade alignment issues, or excess tension. Only by understanding the condition of your shears can we restore them to their ideal form—without over-sharpening or removing unnecessary material.

2. Hammering: The Hidden Art of Tension Correction

If needed, we use precision hammering to correct tension and alignment in the blade. While it may sound old-fashioned, this technique ensures your shears have the just-right tension for a smooth, frictionless feel while cutting. It’s a delicate process—done by hand, with care—so your shears close cleanly and effortlessly.

3. Precision Honing with Japanese Lapping Film: The Edge That Lasts

Instead of using traditional whetstones, we hand-hone each blade with Japanese lapping film—a high-tech material known for its speed and precision. This method delivers a fine, consistent edge that stays sharper longer and minimizes the need for frequent sharpening.

4. Convex Honing: Crafting the Perfect Edge

Using specialized tools and knowledge gained directly from Japan, we hone the perfect convex edge. A true convex edge not only looks better but also slices hair more cleanly, quietly, and smoothly—with less resistance. This shape reduces hair bending and tugging, preserving the integrity of every cut.

5. Hand-Polishing: Bring Back the Shine

After sharpening, we hand-polish each pair of shears to restore their original shine. This finishing touch doesn't just make them look like new—it also smooths out micro-imperfections along the surface, helping prevent future corrosion or buildup from products and moisture.

6. Feeling Check: It’s Not Done Until It Feels Right

We finish every job with a feeling check, adjusting anything that compromises the shear’s smooth, effortless feel. This includes fine-tuning the tension, alignment, and closing action to ensure the shears don’t just cut—they glide.

If we find worn or damaged parts like stoppers or washers, we replace them as needed to restore the full performance and comfort of your shears. These small components play a big role in maintaining balance, reducing friction, and preventing long-term wear.

If something’s not right, we make it right—because performance matters.

Final Thoughts

Great shears deserve great care. Our sharpening process is more than just maintenance—it’s a detailed craft that restores the performance, beauty, and longevity of your professional tools. By combining tradition with precision, we make sure your shears deliver the same smooth, clean cut as the day you bought them—if not better.